There was a problem with the machine closing the aluminum can lids. Namely, when there was a single alarm condition, one “closing machine failure” message appeared on the HMI panel as a collective message from all alarms. Apparently, the control system contactor finished his work on this project too early.

One time, after the emergency condition, the removal of the unknown fault took so long, someone decided to do something about it. These words were spoken:

“Please, do something in the way, in which finding the place of failure will be immediate!”

Urgent topic and worth making the effort.

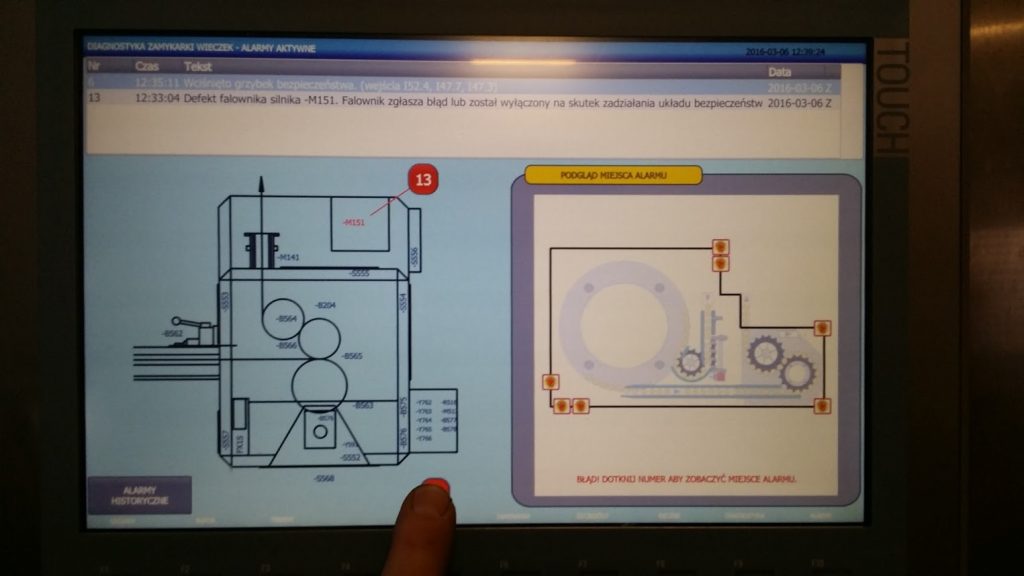

So I started to go through the PLC program (Siemens S7-300) and it turned out that the “closing machine failure” includes 21 alarm states. The first step was to complete the alarm list on the HMI panel (Siemens KTP1200 Basic) and connect the proper bits from the PLC to individual messages. Now a separate message will be displayed for each failure. This is a standard way and does not solve the guideline I got, which was finding the place of failure immediately.

Text messages were additionally equipped with the sensor symbol and the number of digital PLC input. What did it do? Thanks to the sensor symbol, you can quickly find it in the electrical documentation. Thanks to the knowledge of the digital input, you can start searching it right away in the PLC program.

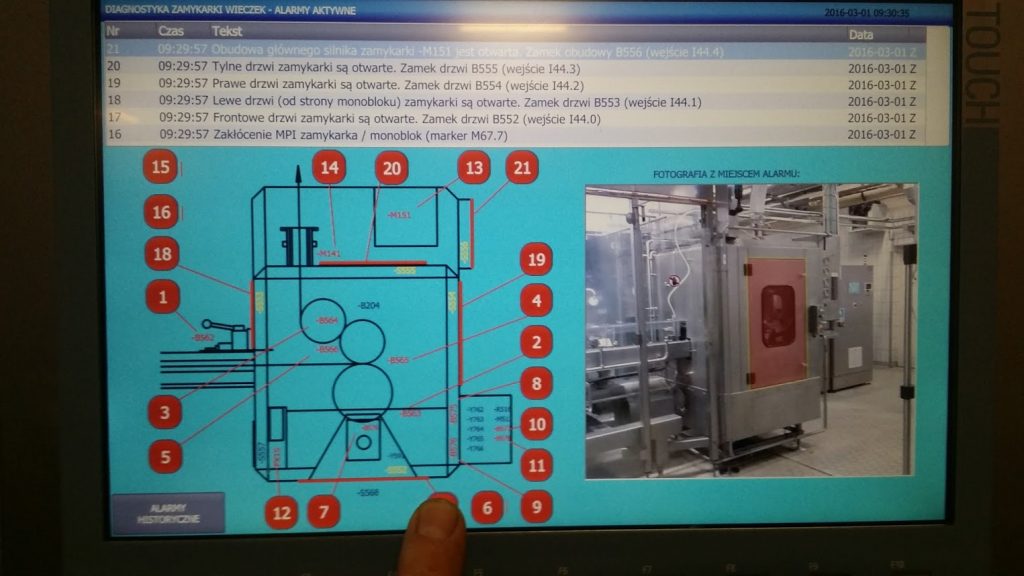

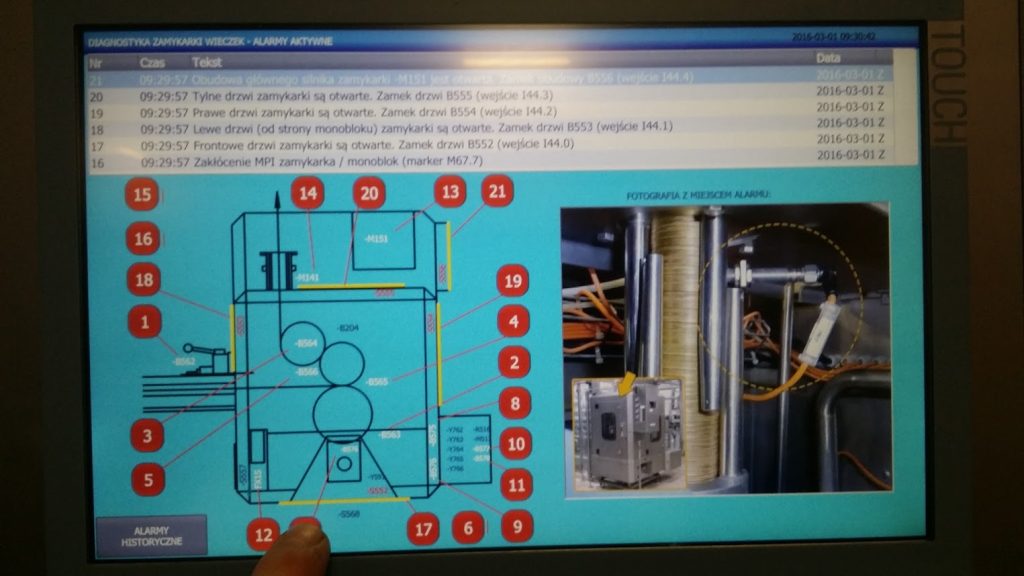

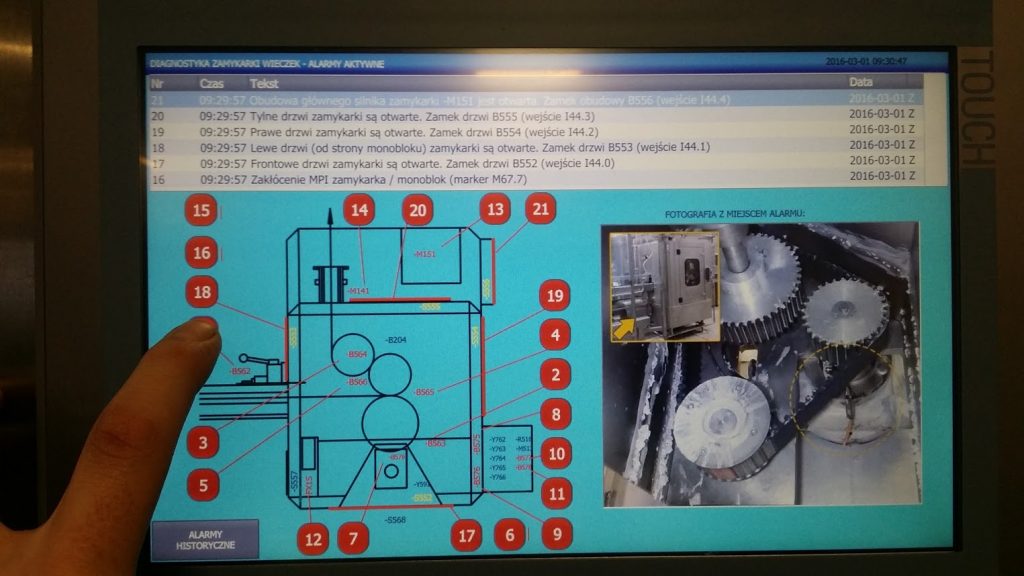

A commonly used method in the HMI panels is a drawing of the object in the cross section and an indication of the place where the alarm occurs. On the screen with alarm message, I made a technical drawing of the machine, on which the alarm numbers appeared and a line indicating the symbol of sensor detecting the emergency condition. This method will significantly improve finding the place of the failure. But will it be the required “immediate”? That was it!

I took out the mobile phone and started photographing all 21 places, I mean 21 sensors detecting alarm states. I thought that the problem will be solved if after touching the icon with the alarm number, a photo will appear next to the exact location of the emergency condition. I stared copying photos from my phone to the computer. Then I add an object on the panel that will allow to change the photo after touching the appropriate icon. Two hours of clicking in TIA PORTAL and it’s ready! I am connecting to the HMI panel, I click DOWNLOAD and…? ERROR! The memory of the panel has been exceeded. It turned out that 21 photographs are too much, at least initially. Each graphic was optimally compresses. Now it’s the time for another attempt to compile and upload the program. It worked! There was even some reserve left in the memory for the next additions. It presents as follow:

The visualization is said to be praised. The method is very practical, although in this panel, the HMI took most pf the space for the program. Some panels have option of expanding the memory by SD or USB card. This can solve the limitation.