If you already had contact with controllers in industrial automation, you have certainly heard about the logic module – LOGO!8 from Siemens. If you haven’t heard about this controller, you should be interested in it and if you would like to learn how to program the controllers, start from this. In this article I would like to present how BIG controller is a small LOGO!8.

When designing the control system, we finally reach the point where the heart of the whole system should be selected: logic controller, PLC etc. In the situation when our control system is extensive, requires complicated process operations and communication capabilities with other devices, then we aim at choosing PLCs. We analyze the demand for the number of digital and analog inputs / outputs, communication protocols, computing power, etc. and then select the appropriate modules for the CPU. However, there is a limit before which investing in more expensive PLC equipment is not necessary and we can take other solutions into consideration. LOGO! 8 controller from Siemens is showing up here. Along with its expansion capabilities, communication options, advanced and simple in use options, this controller means that there are many control systems and LOGO! 8 will manage with them without effort. You will rate it by yourself but first read this article :). At the end I will describe how to easily get to learn programming of this controller without buying it.

LOGO!8 – IDEA

I have reviewed the possibilities and applications of this logical module and on this basis I based the entire content of this article. The idea of the LOGO! 8 is to enable, not only automation specialists, to automate relatively simple tasks. Thanks to the intuitive LOGO! Soft Comfort software and the lack of complicated configuration options (as in the case with some PLC controllers) LOGO! 8 becomes a truly usable device for people with basic knowledge of electrical systems. I suspect that some people may not be aware that their knowledge skills are sufficient to independently build systems based on this controller.

In many control cabinets we are able to observe a number of devices, contractors, relays and time relays, which not only take up a lot of space, but also in connection with the required connections, they cause “wired spaghetti” in cable trays. Here is a great example of how to use LOGO! 8, which by replacing the conventional control system not only saves space in the control cabinet, but ultimately also saves your money. The use of controllers allows the introduction of modifications without the need of breaking electrical connections, that’s why I support such applications. During the tests of this controller I was delighted with the simplicity of programming.

LOGO!8 – POSSIBILITIES OF EXTENSION

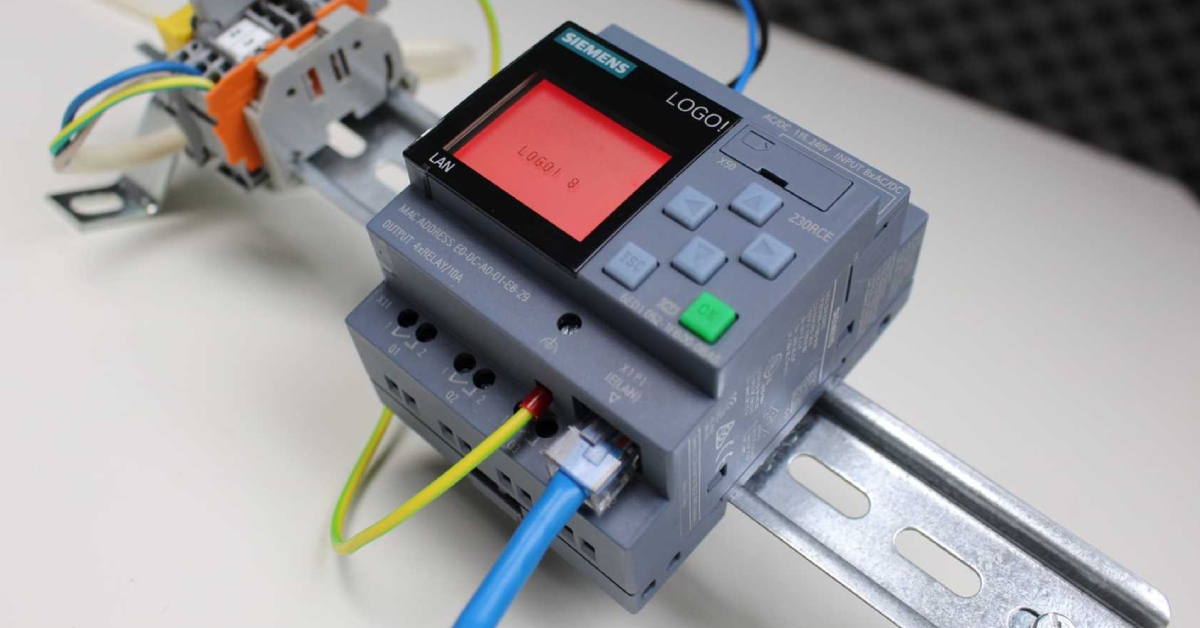

LOGO!8 is a module controller, that means that we can expand it with additional I/O modules or communication modules. This controller is able to handle up to 20 digital inputs, 20 digital outputs, 8 analog inputs and 8 analog outputs (0-10V / 4-20mA / PT100, PT1000). When considering the expanding, we have to take into account the inputs and outputs, that are already on board.

The CPU unit is available in four configurations due to the power supply and configuration of inputs and outputs. There are also CPU units without a display but they do not differ much in price, so they are rarely used.

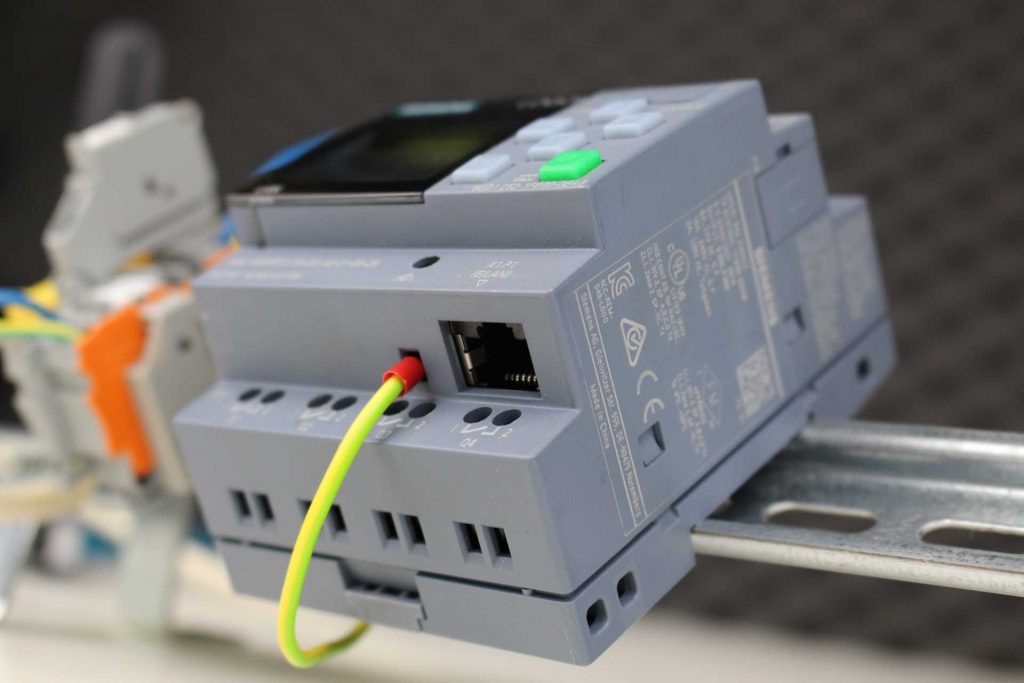

The controller can be additionally equipped with Ethernet communication modules or a communication module in the GPRS / SMS / GPS network. However, if we would like to move the screen of the controller to another place – for example on the door of the control cabinet, this is enabled by our dedicated TDE PANEL.

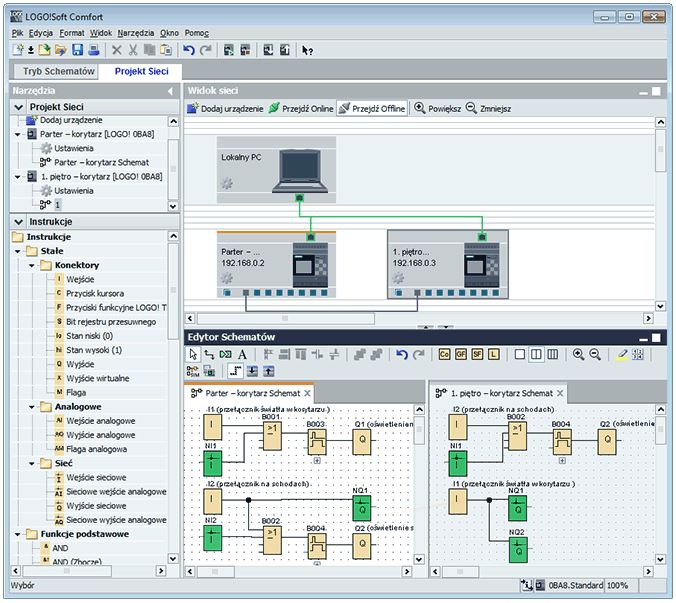

LOGO!Soft Comfort – DEVELOPMENT ENVIRONMENT

LOGO!8 controller is programmed in LOGO!Soft Comfort. Its design is very much like TIA Portal, which programs Siemens Simatic S7 controllers.

We have two languages, block FBD and ladder LAD, for building the program logic. In my opinion, we can much more efficiently program LOGO!8 in FBD language and for beginners I recommend this language, as the first, in LOGO!Soft Comfort. We have 43 functions for various applications, which give you a lot of opportunities as the equipment at this price. All functions are described in detail in the Siemens manual, which can be downloaded in PDF format – a link at the bottom of this article.

It is worth paying special attention to the fact that the trial version can be downloaded from the manufacturer’s website for free. The most important is that DEMO has a refined controller simulator, so it gives huge opportunities for beginners for learning. The trial version is not limited in time, we only cannot upload the program to the physical driver.

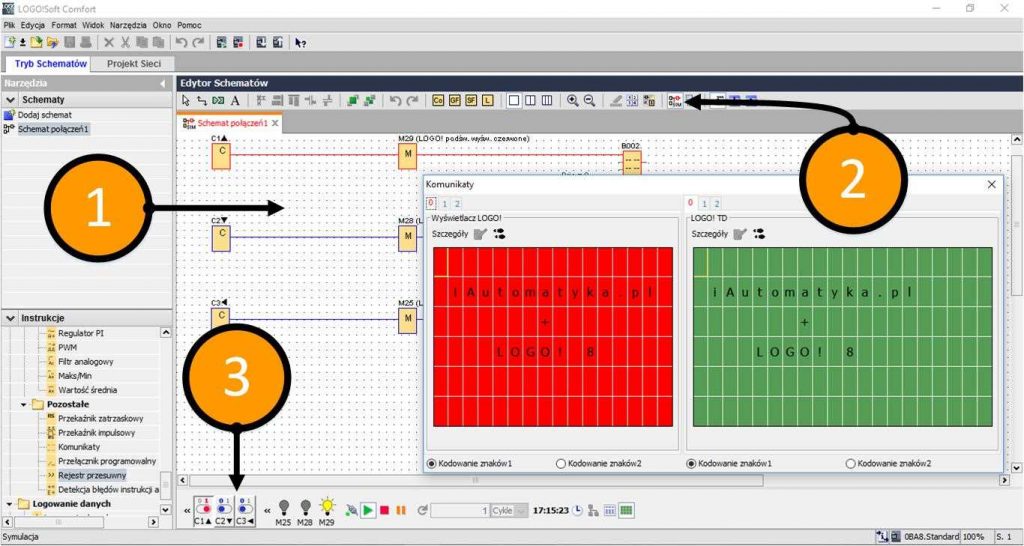

3 steps for simulation in Logo!Soft Comfort:

- Create a program.

- Run up the simulation mode.

- Simulate the program operation.

Logo!Soft Comfort is a very friendly environment where, just like in TIAPortal, most of the actions we are able to do using DRAG&DROP method. A big advantages is also expanded program help – after pressing the F1 button we have the access to huge knowledge base.

As I mentioned in the introduction, programming LOGO! 8, thanks to “refined restrictions”, it becomes very easy. By that I mean that the parameterization of each function is limited to the minimum necessary, which in this case I consider to be an advantage of these devices. Thanks to this, this driver is dedicated to a wide range of people who do not necessarily have to be specialists in programming – just basic knowledge about logical operations such as AND, OR, NOT, etc.

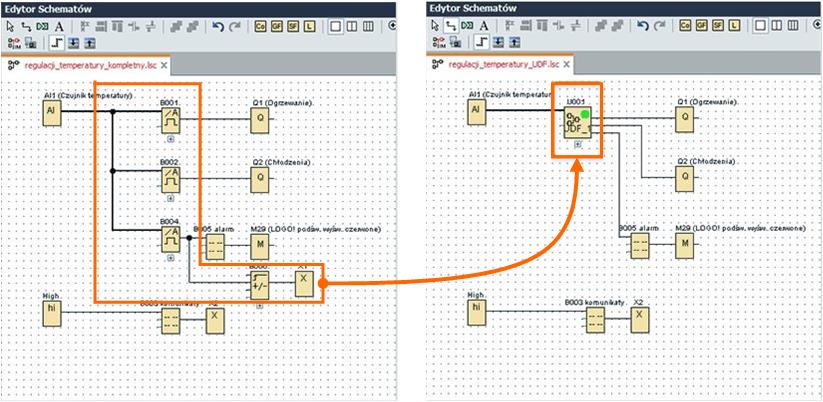

During tests and overviews of the possibilities of LOGO!8 I was surprised by one function – UFD which is User Defined Function. This option is extremely useful in situation, when we have repeated operations in the program. Thank to this we have less work and the program looks clearer.

LOGO!8 – DATA LOGGING

Besides basic logic operation we have at our disposal data logging (archiving) function – Data LOG. It makes possible to register I/O values and current values in used function blocks and M markers areas. Data is saved at specific time intervals or in the case of specific events in the controller. The collected information is stored in a CSV file (to be played in Excel) directly in the LOGO! 8 or on a Micro SD memory card. The data logging function can only be used once in the program, which is enough.

The maximum number of lines saved in the CSV file is 20,000. After this limit, LOGO! 8 will automatically save the current file and create a new file starting data logging again.

LOGO!8 – DISPLAY

Built-in display is not only used for operating the system menu for configuration purposes. We can take control on it from the program level to display specific process values or logic states. We have 6 lines of 16 characters each. LOGO! Soft Comfort also allows you to configure up to 50 messages, e.g. started up after exceeding an analog value, logic state or button on the controller. The displayed alarms can be scrolled if there are several alarms and set to be confirmed by the user. It is also possible to change the color of the backlight from the program level to white, red and as it is declared by the producer … amber :).

The entire service of additional messages on the display takes place without special configuration or setting up a new project. We add a new “Message text” block to the connection diagram, and configure its options for the message screen in its options. We have all possible options in one window and I think that in the first use after just a few minutes everyone will be able to freely configure the screens in LOGO!8.

In addition, the system menu has many useful options. We are able to change the parameters of each function used in the program and even edit the program from the panel. There is also an option to secure parameter changes, which may be useful when we give the layout to the client and we do not want to have access to some functions.

LOGO!8 – COMMUNICATION

LOGO! 8 has one Ethernet port and through it we connect our computer. This is not the only function of this port. The network can be expanded to 16 devices, these can be: LOGO! controllers, Simatic S7 controllers and a maximum one HMI panel. To expand the network we need to use Ethernet switches, e.g. LOGO! CSM with four RJ45 sockets.

As I learned from the LOGO!8 programming course data exchange between LOGO controllers takes place in one project and without special communication blocks (as in PLC). Here, it is enough to use “network inputs and outputs” which is a great convenience for users without specialized knowledge. The LOGO! Soft Comfort software has two editing modes of the schematic mode, i.e. a classic view and a network project in which we can configure network connections and run program edit windows for several LOGO! 8 controllers.

In addition to Ethernet communication, we can equip the LOGO! 8 with the LOGO! CMR 2020 module, which will enrich the functionality with a GPRS / SMS / GPS network.

Thanks to this device, among other things, we can send orders for the LOGO!8 controller via SMS or to send questions about LOGO!8 parameters and status. This module also has a GPS thanks to which we can remotely find out where the controller is located. This option will be used in objects that move. An additional option is the synchronization of the clock time of the controller, both GPS, cellular network and even the Internet.

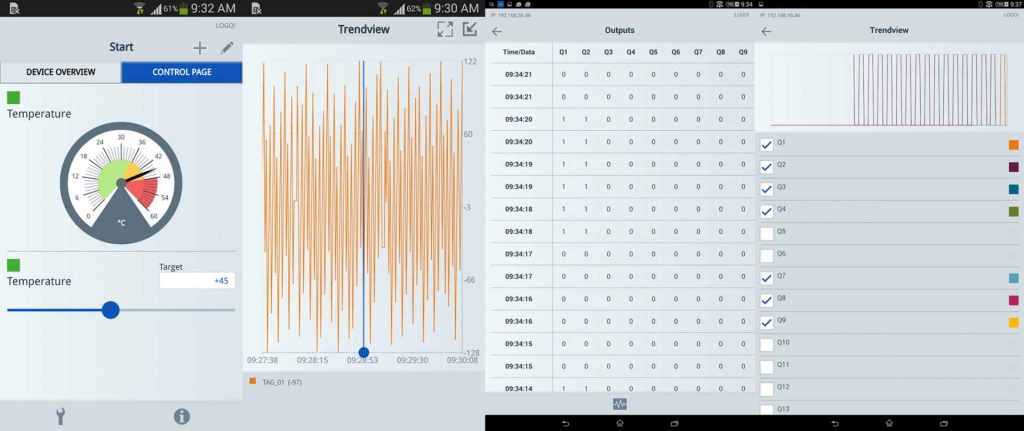

LOGO!8 – WEB SERVER AND SMARTPHONE

If it’s still not enough for you, the LOGO!8 has a built-in WEB SERVER. Thank to this functionality, we are able to have access to all the functions of the controller and the TDE panel from the level of the web browser. Of course, both LOGO! 8 and the device on which we want to watch the controller must be in the same network. This means that if we connect a WIFI router to the network, we will have access to the controller, e.g. using a smartphone – just enter the IP address of the controller in the browser. The big advantage is also the way how the page is displayed in a web browser – everything is in responsive mode, so the view automatically adapts to the resolution of the device.

In addition to remote access to LOGO! 8 via the web browser Siemens has released the free LOGO! on Android. In the above photo you can see the WebServer preview from the dedicated Smartphone application. In addition to the display preview, this application provides a lot more diagnostic possibilities. We can see changes in the time of the state of inputs, outputs, markers and other variables used in the program in the form of a table or trends (charts). The application also allows you to change parameters, set points, limits, etc. We can download it from Google Play.

Remote access to WEB SERVER can be protected by the password, so we can use it in industrial factories – I can’t wait to take control over control system via my smartphone :).

LOGO!8 – HOW TO START LEARNING THE PROGRAMMING OF THE CONTROLLERS

Free access to demo version of LOGO! Soft Comfort with built-in simulator makes, that this is one of the best opportunities for learning the programming of the logic controllers. While browsing the online forums, “LOGO!” is the most common answer for the question “How to start learning the programming of the controller?”. I can also truly recommend this controller for the beginning. Now I’m going to show you where to start with LOGO!.

STEP 1: Download and install the software.

The first thing you should do is downloading the LOGO! Soft Comfort software from the producer’s website. Enter this website w3.siemens.com. Chose the version suitable for your computer (32 or 64 bit). Install the program.

STEP2: Start LOGO!8 PROGRAMMING TRAINING.

Here, the LOGO! producer deserves an applause! Siemens has prepared an interactive online training available for free. The whole is developed in so much details that it allows you to go through the first steps with a new device, which usually starts with wandering and many questions. In this case, it is enough to invest about 1.5 hours (under the condition that we do the exercises together with the teacher) and further controller, then more and more ambitious programs are built from scratch and the actions of some functions are explained. There will be also lessons about communication, WEB SERVER or SMS. During the training, we may encounter control questions and tests, which at our discretion may be omitted. We can start the training on the SIEMENS website.

STEP 3: Extend your knowledge.

The first rule of the programmer is that if he wants to quickly get directions in a given development environment, he presses the F1 key! In LOGO! Soft Comfort the help system is very extensive but also. In addition, it is worth to obtain the following documentation:

LOGO!8 – INTERESTING FACTS

- Communicational possibilities with KNX systems – LINK

- New version of LOGO!8 working with communication in Modbus TCP protocol – LINK

LOGO!8 – SUMMARY

LOGO!8 controller offers great opportunities. It is able to cope with many control systems in both domestic and industrial installations.

LOGO!8 is not included in the class of PLCs, because of the lack of controllability associated with time pressure, e.g. for fast machines requiring interrupt. The presented controller will not be able to handle complex math operations. The communication capabilities are not adapted to complex open communication, such as PROFINET for basic data exchange.

LOGO!8 can be used for ambitious tasks, but you should not struggle with its limitations and use a PLC such a Siemens S7-1200 at the right time.

In my opinion, LOGO!8 has the basic advantage, which is its simplicity in use. It is enough to know the basic issued with discrete systems, such as combining AND and OR gates, and next issues, such as counters and time relays, will be elucidated during further rules of LOGO! Programming.

General access to teaching materials, software with a really good simulator and a programming training prepared by Siemens makes LOGO! at the forefront of controllers from which we should start adventures with PLC. There is nothing else to do but start the training 🙂

Certainly many of you have already dealt with LOGO!. I would like to know how many people have had contact with this driver, so I am asking you to leave a comment under the article. Write where and in what situation you had contact with LOGO! 🙂