I got a lot of questions from young automation specialists about assistance in choosing the right PLC controller for learning. A common choice is Siemens S7-1200 PLC starter set, LOGO! 8, Fatek, Unitronics or the PLC. When choosing a controller it is worth, among other things, to pay attention to its power supply.

For example, Siemens S7-1200 CPU 1212 AC/DC/RLY controller is powered by 230V AC. To create your first ladder, all you need to do is connect to the 230V socket. This is an obvious matter and it’s without any doubt. What if we have a controller powered by a constant voltage 24V, for example CPU 1212C DC/DC/RLY unit? We will not connect this to the 230V socket… unless we want to test the power supply of such controller (I do not recommend it!). In such cases we must have a power supply that converts 230VAC to 24VDC.

How to choose the right power supply? To answer this question, we will build our own PLC + HMI set, calculate the power consumption and select the appropriate power supply. Let’s do it!

Our set will consist of the following elements:

| PLC Siemens controller SIMATIC S7-1200, CPU 1214C DC/DC/RLY (6ES7 214-1HG40-0XB0) |  |

| Siemens digital input/output module SIMATIC Module SM 1231, 8xAI (6ES7231-4HF30-0XB0) |  |

| Siemens RS485 communication board SIMATIC Module CB 1241, RS485 (6ES7241-1CH30-1XB0) |  |

| Weintek touch panel Panel eMT3070A 7.0” (MT6070IE) |  |

VOLTAGE

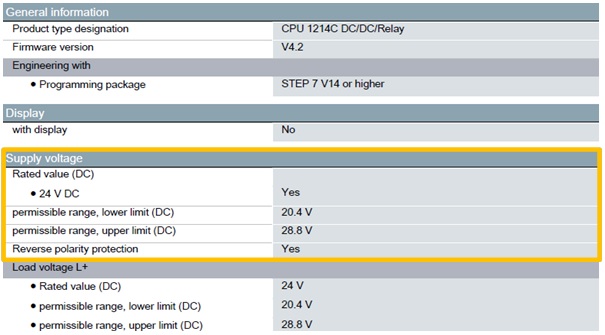

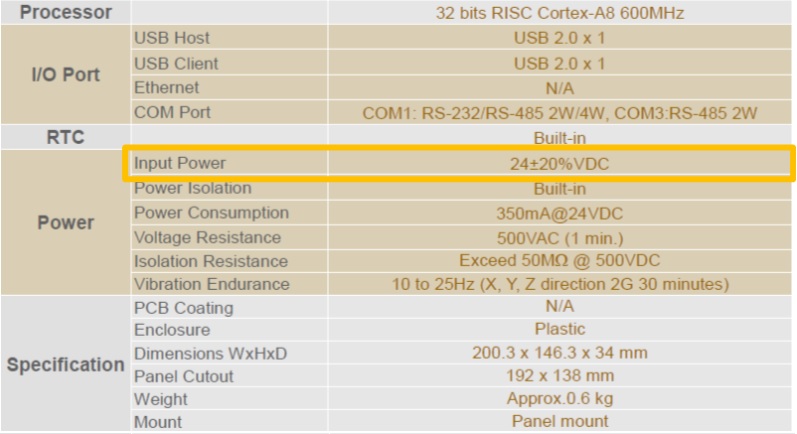

Link with the technical documentation is placed next to each element, let’s take a look at all instructions. The first thing you should pay attention to is of course the type of power supply to the element. The instructions are in English so we are looking for keywords such as: “Power Supply”, “Input Power”, “Supply voltage”.

Analyzing the data, we can conclude that all elements are supplied with 24VDC, the SIMATIC CB 1241 module has been deliberately omitted in the above statement because it does not require a separate connection to the power supply, which is drawn directly from the CPU. In addition, we can also see that parts of the manual provide information about the range of voltage tolerance for normal operation. In PLC as well as in HMI, the tolerance is ± 20%.

CURRENT AND POWER

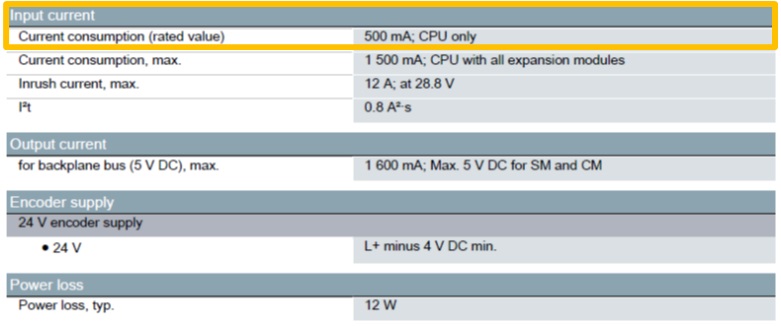

Going further, the information indicating the current consumption is hidden under words: “Power Consumption”, “Current Consumption”.

CPU 1214

The average power consumption of the controller is 500mA. Please note that if it is equipped with all expansion modules, the current consumption will increase up to three times! This should be remembered when choosing a power supply. In the case of the desire to extend our set in the future with further modules, the power supply that has been selected without a large reserve will be insufficient.

Using the formula for electric power P = U * I, let’s calculate:

Power consumed by the PLC: 500mA * 24VDC = 12W

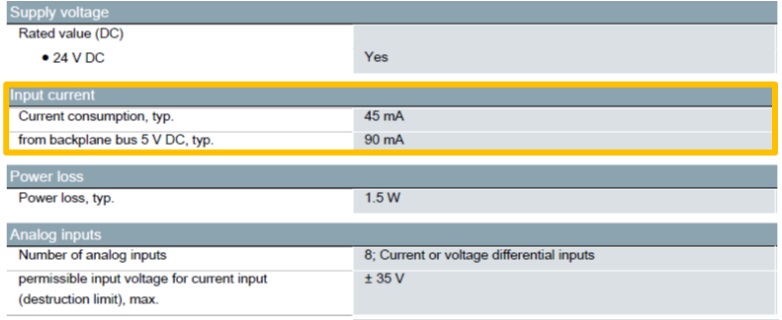

Digital input/output module SM 1231

The average power consumption of the extension module is 45mA. However, remember about the expansion bus, which drawn a current of 90mA at 5VDC.

So we count:

The power consumed by the module: 45mA * 24VDC = 1,08W

Power consumed by the extension bus: 90mA * 5VDC = 0.45W

The total power absorbed by the module will be 1.53W.

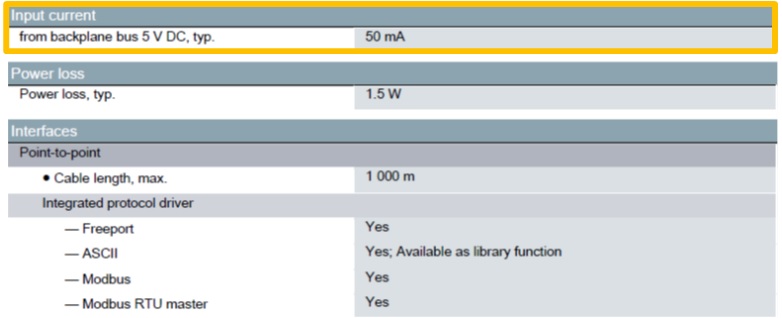

Communication module CB 1241

The last element from the controller group is its communication module. It is powered from the controller extension bus and takes 50mA at 5VDC. The manual contains information that the module consumes 1.5W power, instead of calculations, you can adopt information from the manufacturer.

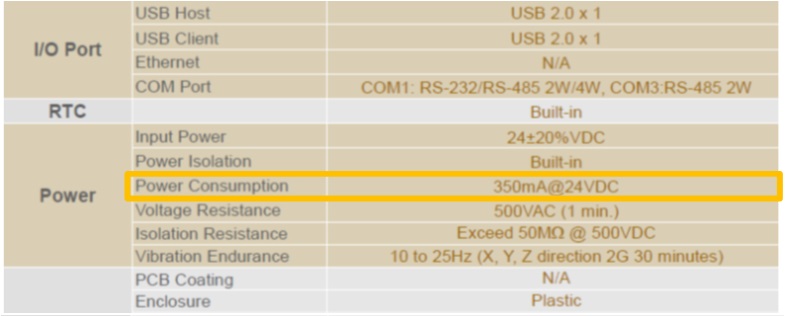

HMI MT6070iE2 panel

The current that the touch screen consumes in 350mA. Thus, we again use the formula P = U * I and we get:

Power consumed by HMI: 350mA * 24VDC = 8.4W

Power of the set

We have already calculated the power of individual elements. Now we have to calculate the total power:

Power consumed by the whole set: 12W + 1.53W + 1.5W + 8.4W = 23.43W

Now it’s time to choose the right power supply for the calculated power of the set, which is rounded 23.5W. We must remember that the power supply produces an average power of not less than 23.5W. Its output current should be bigger than:

23,5W / 24V = 0.98A

SELECTION OF THE POWER SUPPLY

Let’s compare the parameters of two power supplies for the needs of our set:

| Power supply Mean Well DR-15-24 |  |

| Power supply Mean Well RS-50-24 |  |

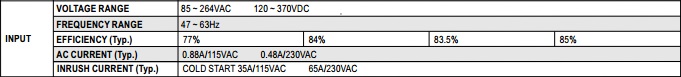

What are we looking for? First of all, we must be sure that we’’ be able to supply such a power supply. The most common voltage is 230VAC and 50Hz frequency from our household socket. Let’s check what voltage the power supplies need:

Both power supplies operate in similar voltage ranges 88-264VAC and frequency 48-63Hz. With regard to input power, we can safely use both power supplies. Both of them match to our set, now we need to check their output parameters. What are we looking for? The fist most important parameter is the output voltage. Elements of our set are powered by 24VDC voltage, so we should look for his one. The next parameters will be output power and current.

The first one, the DR-15-24 power supply:

DC Voltage. The voltage at the PSU output is 24VDC, as much as we need.

Rated current. Current range. The output current range is within 0-0.63A. The current which will be taken by our set according to the calculation is 0.98A. At this point, we should already reject this power supply, but let’s analyze another parameter which is the power produced.

Rated power. The power that the power supply produces is 15.2W. Also, this is not enough. The power supply is definitely too weak for our driver and panel pledge.

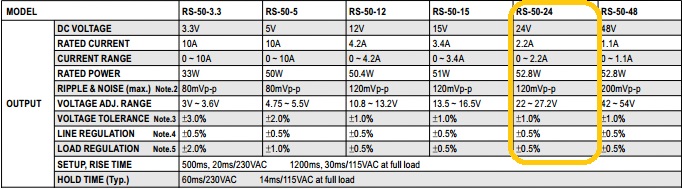

The second one, the RS-50-24 power supply:

The output voltage of the power supply as in the previous one is 24VDC.

The next most important parameters: current and power. Average output current within the limits of 2.2A. The generated power is 52.8W. In the case of this power supply, the parameters exceed the current and power twice. We can choose it as the last element of our set. It is oversized and of course we will pay more for it than in the case of a power supply loaded with its nominal current. However, the benefit is than – when choosing such a power supply we will increase its reliability and significantly extend the trouble-free operation time. An additional advantage is the reserve of power that we can use in the future to expand the control system.

There are several practices and principles of selecting the power supply, for example we can assume the principle that a power supply should be selected with at least 20% more power than the nominal control system’s demand. However, in practice it turns out that it is worth having more of this supply.

In addition, it is worth remembering to secure both power supply (fuse in front of the power supply) and the protection of devices (fuse or fuses behind the power supply).

WHERE TO FIND THE POWER SUPPLY?

We can recommend you to visit online store EMBiA.pl where it is possible to conveniently filter the parameters of the power supplies. It is worth paying attention to the Mean Well power supplies, which are very popular in the automation industry.

Author: Grzegorz T.